Want to speak to one of our experts?

To ensure the utmost quality, BGA only manufactures 100% brand new Power Steering Pumps, avoiding the inconsistencies that can occur with remanufacturing. Every pump is manufactured using the latest OE technology in our state-of-the-art, environmentally controlled, facility.

We can guarantee that 100% of our Power Steering Pumps are rigorously tested throughout the manufacturing process before being subjected to multiple levels of quality control prior to being released for sale. All of which means that we are supplying our customer “The Smarter Choice” on aftermarket Power Steering Pumps.

The Smarter Choice, Brand New BGA Power Steering Pumps

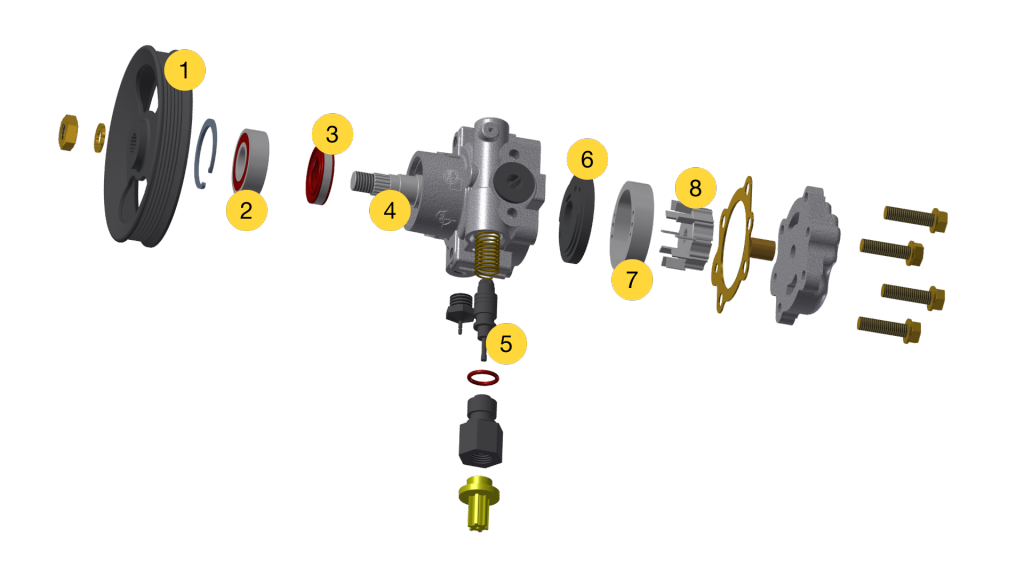

Dimensionally critical item. A pulley which is out of tolerance could lead to noise, vibration and potentially can cause premature failure of the pump.

Dimensionally designed according to OE parameters, paying special attention to V-rib profile, pulley thickness and welding sections

Endurance tested to ensure longevity of the pulley

Developed according to OE configuration to ensure same load bearing capacity.

Endurance tested ensuring lifespan.

A spring-loaded lip seal at the front of the pump housing prevents fluid leaks between the pump shaft and housing.

All seals are manufactured to OE design, drawing on over 90 years of sealing manufacturing experience.

Machining tolerances to ensure an accurate fitment of all the components, especially grooves for rotor fitment and performance.

Material selection to ensure its lifespan.

A precision-fit valve controlled by the spring and fluid pressure.

Every flow control valve is tested prior to fitment in the pump to ensure its correct relief pressure and again once the pump is assembled.

Performance test is benchmarked comparing with OE specification.

The high-pressure fluid is forced into passages in the thrust plate. The fluid then goes to the flow control cavity where the valve regulates the fluid pressure delivery, according to the steering racks demand.

Dimensional tested to ensure the correct delivery pressure.

The vanes follow the elliptical surface of the cam ring, and are designed to ensure that the high pressures required to service the steering rack are achieved at a consistent level.

Clearance between the cam ring and rotor, hardness and surface finish are tested to ensure longevity.

As the pulley rotates the rotor, a centrifugal force causes the vanes to slide out of the rotor slots. When the area between the vanes expands, a low-pressure area occurs and the fluid flows from the reservoir into space between the vanes. As space then shrinks the fluid is pressurised.

Dimensional tolerances of the components and clearance between them, hardness and surface finish are tested to ensure consistent tolerance between the rotor and vanes.

Wait… Did we mention BG Automotive’s rigorous testing program?

The pumps are tested throughout the manufacturing process, to ensure that they are matching the OE specifications. Once assembled the Pumps then pass through multiple levels of quality control, the first step is the dimensional accuracy of the product, BGA Pump vs. Technical Drawing vs. OE Master Sample.

The final test includes performance testing, simulating real-world driving conditions. All testing for the Power Steering Pumps is carried out by our experienced Technical Engineering Department.

Leak Test

Preformed at various stages throughout the production. Ensuring that there are no air/fluid leaks from the seals or the casting. Any leak could lead to the steering system running dry or the pump not delivering the correct pressure.

Pressure Test

Every control valve is checked prior to fitment into the pump. Moreover when the pump has been assembled and dimensionally and leakage tested, the delivery pressure of the pump is checked again, to ensure the pump is delivering the correct pressure, for example 100 bar ± 5 bar.

Flow Performance Test

Generating a performance curve graph, the test measures flow delivery data, at various pressure and RPM. The graph is then automatically compare to the OE benchmark, with a pass / fail system.

Volume Efficiency Test

Performed on every pump, volumetric efficiency is the measurement of how close the actual volumetric flow rate from the pump is to the theoretical volumetric flow rate, the pump is tested to ensure that it is within the specified OE tolerance.